March 2025

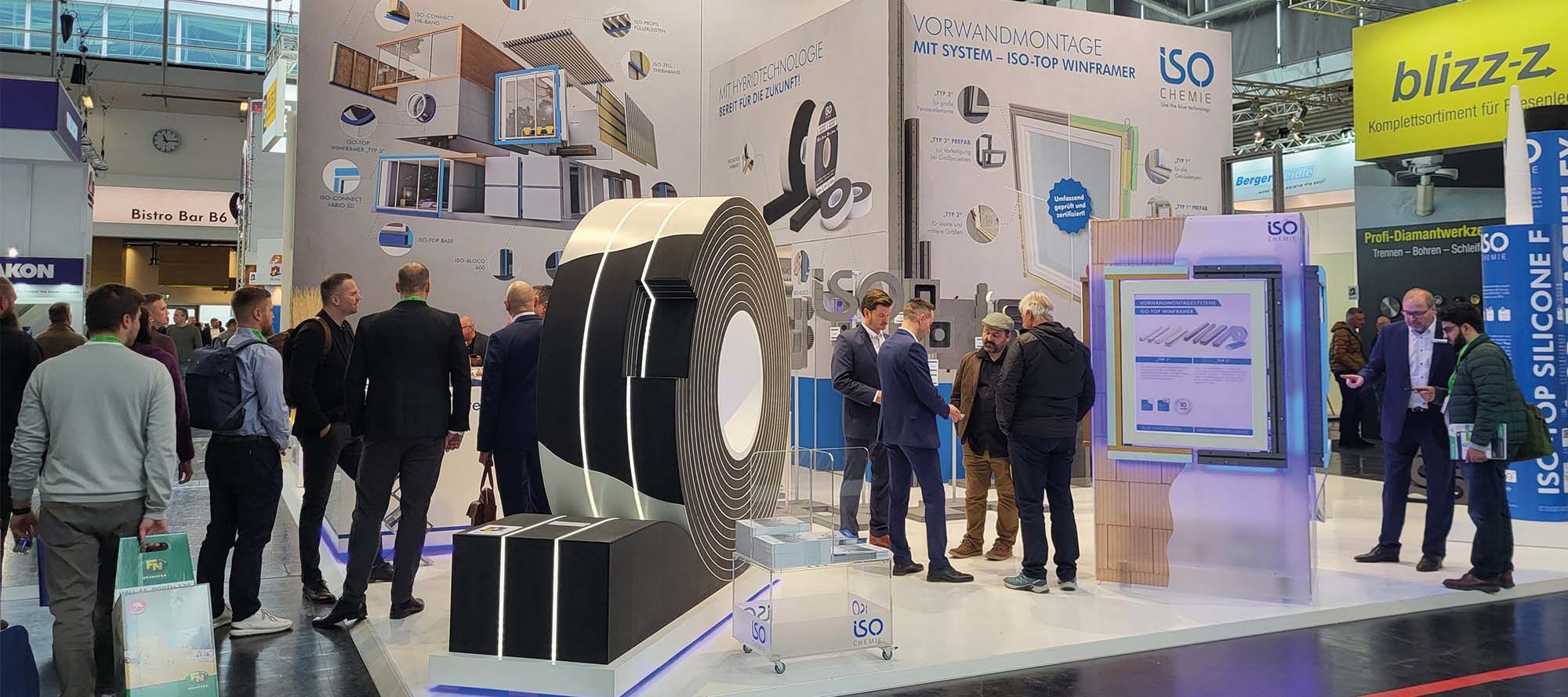

MULTI-FUNCTIONAL TAPE ISO-BLOCO MULTITEC AWARDED GOLD MEDAL AT BUDMA

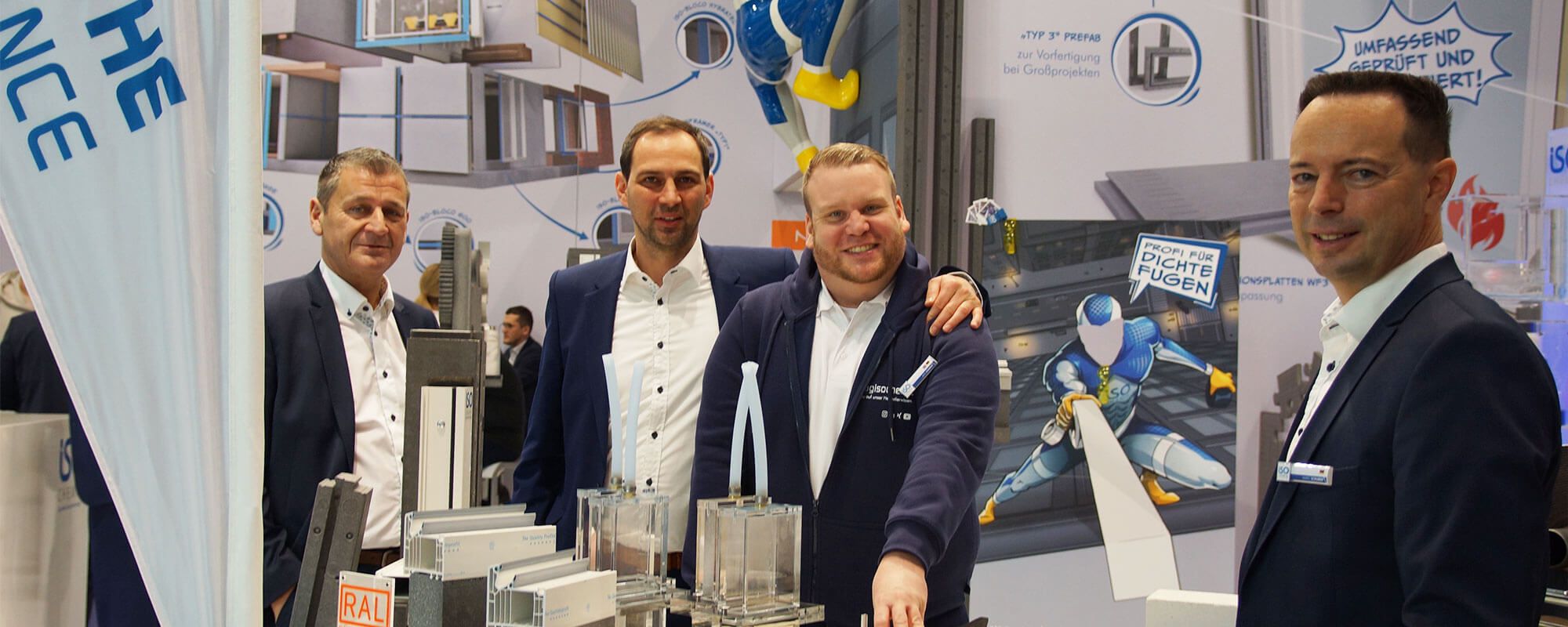

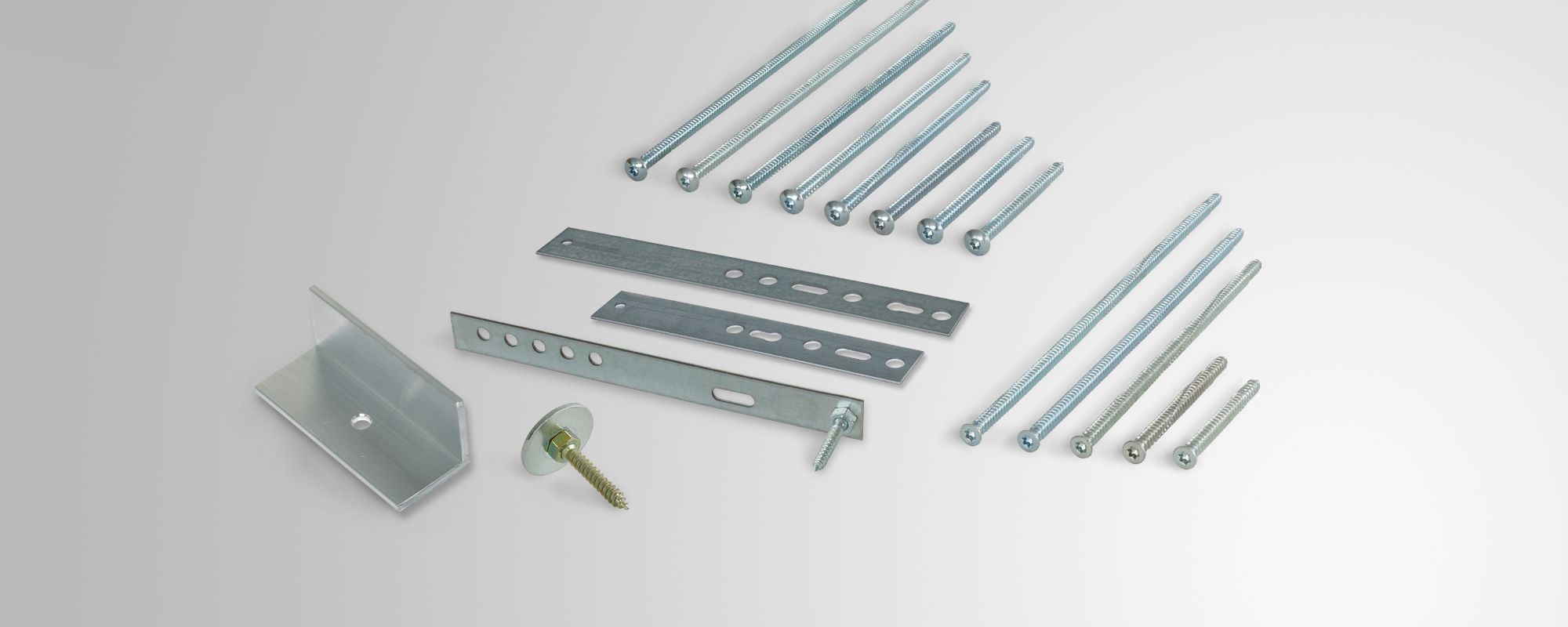

ISO-BLOCO MULTITEC – our innovative multi-functional joint sealing tape – was awarded the coveted “Gold Medal” at the BUDMA trade fair. During the fair, trade visitors to our stand were informed about the many benefits of window installation with the MF1-tested 3-level tape with hybrid technology.

Learn more