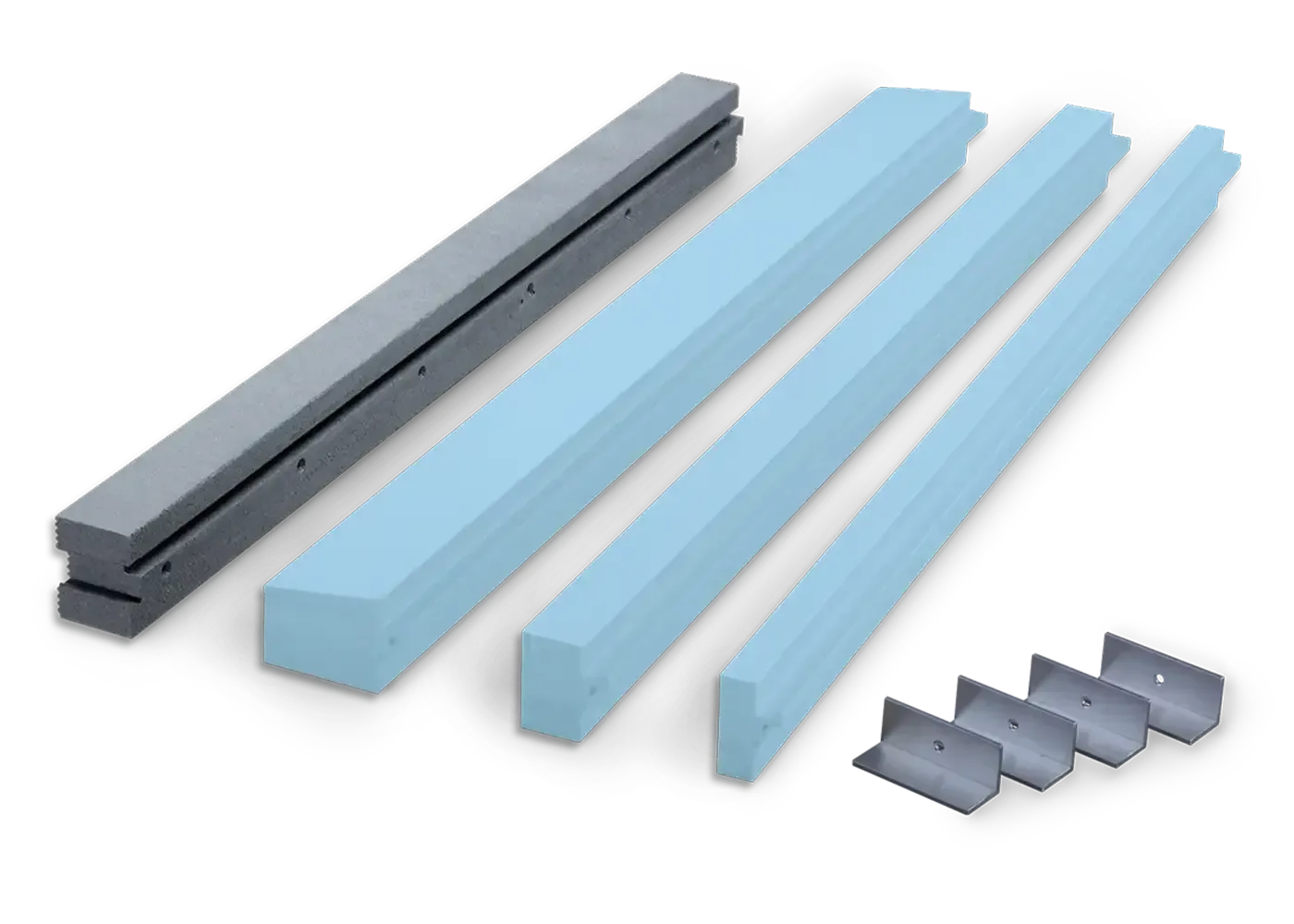

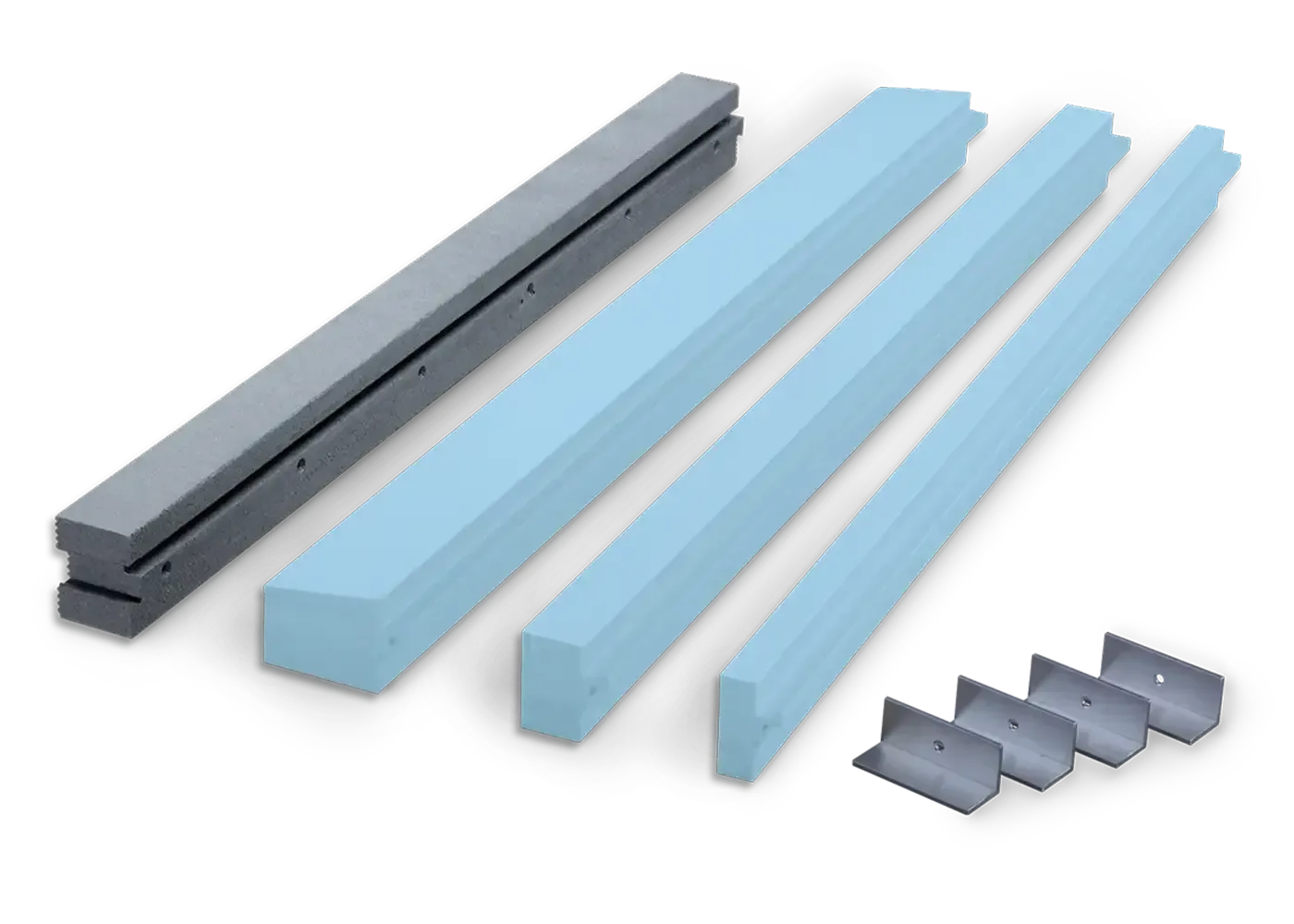

IN FRONT OF WALL INSTALLATION SYSTEM – ISO‑TOP WINFRAMER „TYPE 3“

High load-bearing capability and load transfer in one

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 3“ is made up of load-bearing, thermally insulating system profiles made of high-compressed THERMAPOR. The excellent thermal conductivity of the moulded parts guarantees perfect integration in the EWIS and optimum Ψ-values (Psi). Thus thermal bridges are optimised and a high degree of insulation achieved in the cavity area, what prevents the risk of mould formation in the connection area around the window opening.

The „TYPE 3“ provides a high load-bearing capability and load transfer in one. The high density of 150 kg / m3 not only provides a very good load-bearing capacity for bearing window weights, it is also sturdy enough to transfer all other loads safely to the masonry. The ISO-TOP WINFRAMER

SYSTEM PROFILES can be further reinforced using bearing brackets made of aluminium. With large elements in particular, this leaves enough scope for increased loads and fulfilment of the requirements set out in TRAV / DIN 18008-4 and the ETB directive.

A high load-bearing capability and load transfer

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 3“ provides a high load-bearing capability and load transfer in one. The high density of 150 kg/m³ not only provides a very good load-bearing capacity for bearing window weights, it is also sturdy enough to transfer all other loads safely to the masonry. The ISO-TOP WINFRAMER SYSTEM PROFILES can be further reinforced using bearing brackets made of aluminium. Tightly fitting console slots have been integrated in the system profiles for this purpose. With large elements in particular, this leaves enough scope for increased loads and fulfilment of the requirements set out in TRAV and the ETB directive.

Easy installation process

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 3“ can be used for the installation of windows in the insulating layer. The wind suction, dead and casement loads are absorbed directly by the ISO-TOP WINFRAMER SYSTEM PROFILES and transferred to the load-bearing wall. To achieve this, the ISO-TOP WINFRAMER SYSTEM PROFILES are glued directly to the masonry using the hybrid polymer-based system adhesive ISO-TOP FLEX-ADHESIVE WF and aditionally screwed in place. The mechanical attachment of the window elements is by means of standard window screws. Multi-functional joint sealing tapes or window connection foils from our ISO³-WINDOW SEALING SYSTEM range are ideal for sealing the windows.

Optimum length adjustment

The system profiles have a dovetail connection on the end for quick and easy installation. This allows the system profiles to be fitted together easily and practically. The joints are sealed using the system adhesive ISO-TOP FLEX-ADHESIVE WF before the system profiles are fitted to the wall surface. There are special adhesive grooves in the butt joints for this. Suitable lengths can be prepared in advance in the workshop.

For individual adjustment to the External Wall Insulation system, the ISO-TOP WINFRAMER SYSTEM PROFILES have a through groove on the front. This contains clamping fins to fix optional insulating profiles and window sill moulds in place.

- extensive individual tests by testing institutes**

- RC2 and RC3 tested for the installation of burglar resistant windows and doors

- optimum integration in EWI systems optimisation of the Ψ-value

- simple installation thanks to the dovetail connection

- ideal basis for 3-level-sealing with multi-functional joint sealing strips

- excellent for energy-related building renovation

- complies with the requirements of the Building Energy Act and the recommendations of the RAL “installation guide”

- certified Passive House component

- 10 Year Function Warranty*

* On the conditions of the manufacturer (available on request)

** In front of wall installation systems are currently not subject to any regulation by the DIBt. Approvals such as aBG or abZ must therefore be covered by individual tests. Details on approval as in front of wall installation system for building projects must be obtained individually from the responsible planning office.