January 2026

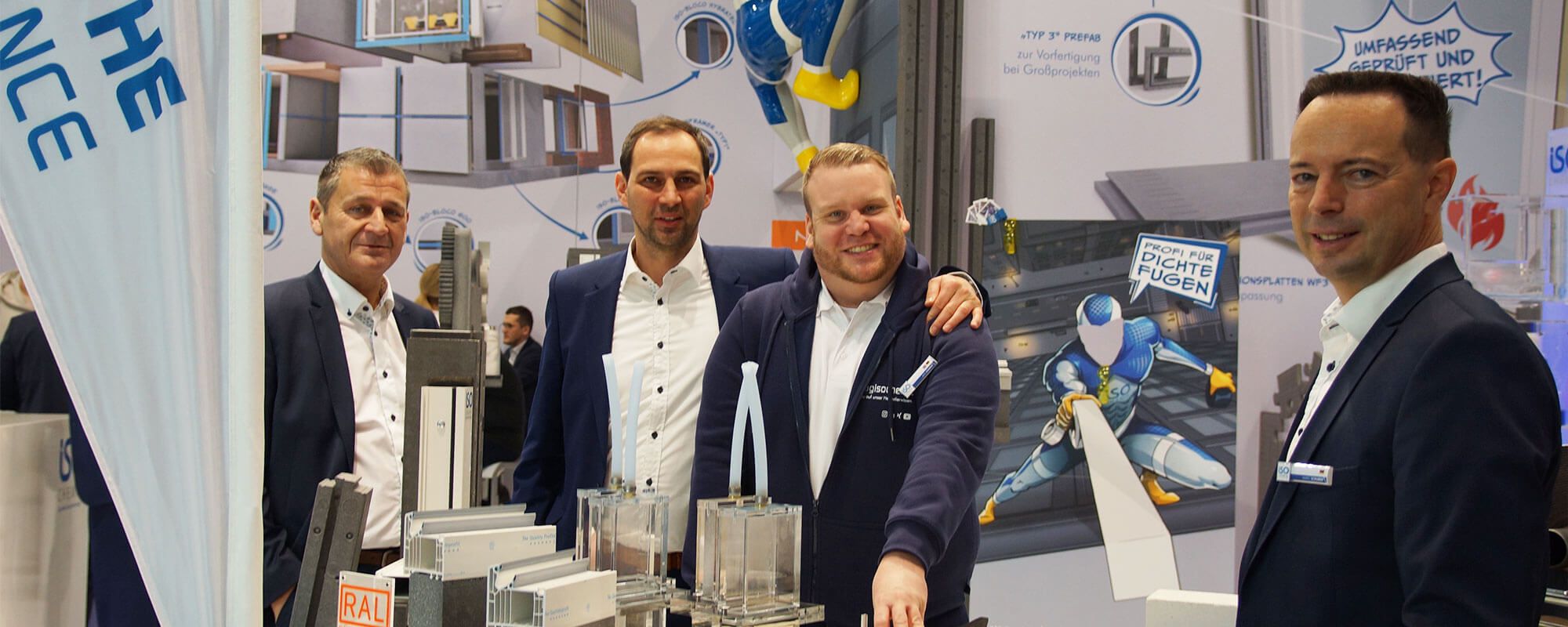

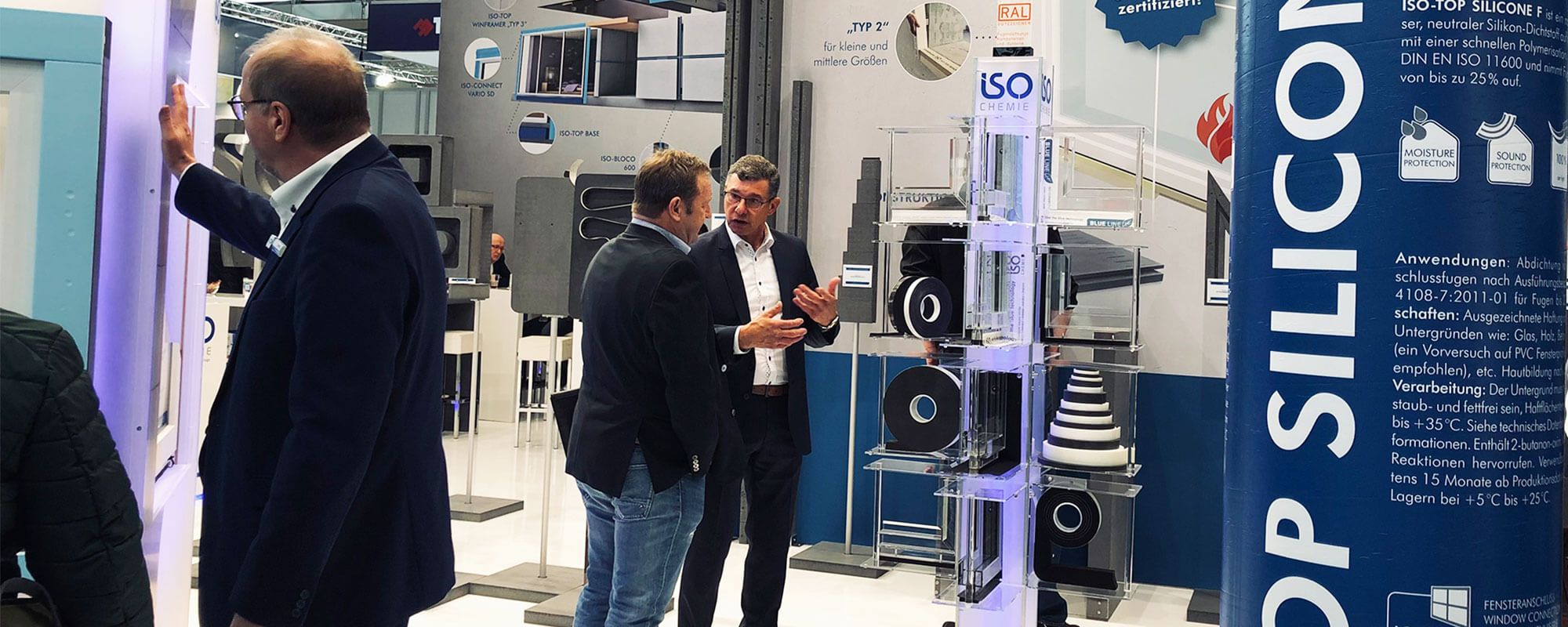

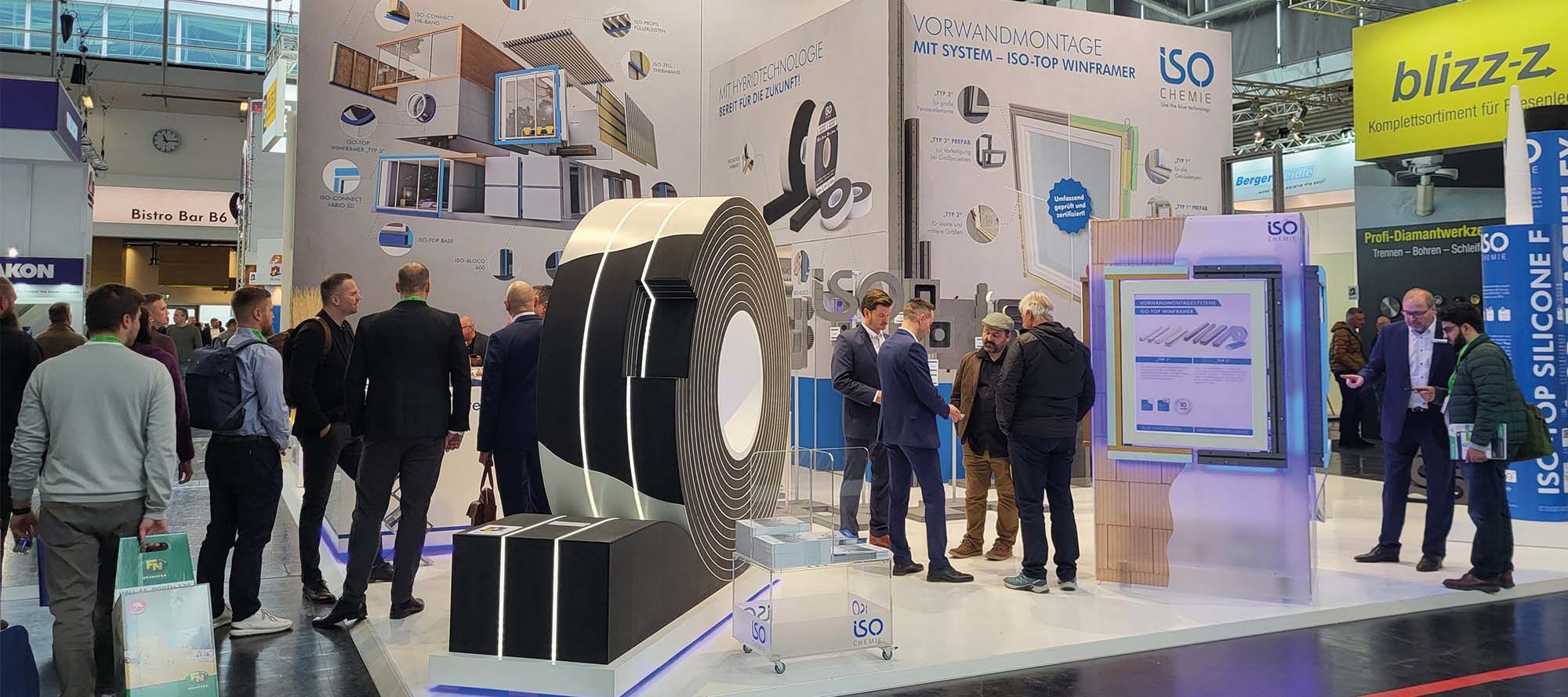

ISO-CHEMIE AT FENSTERBAU FRONTALE: FOCUS ON “SEALING – NEXT LEVEL”

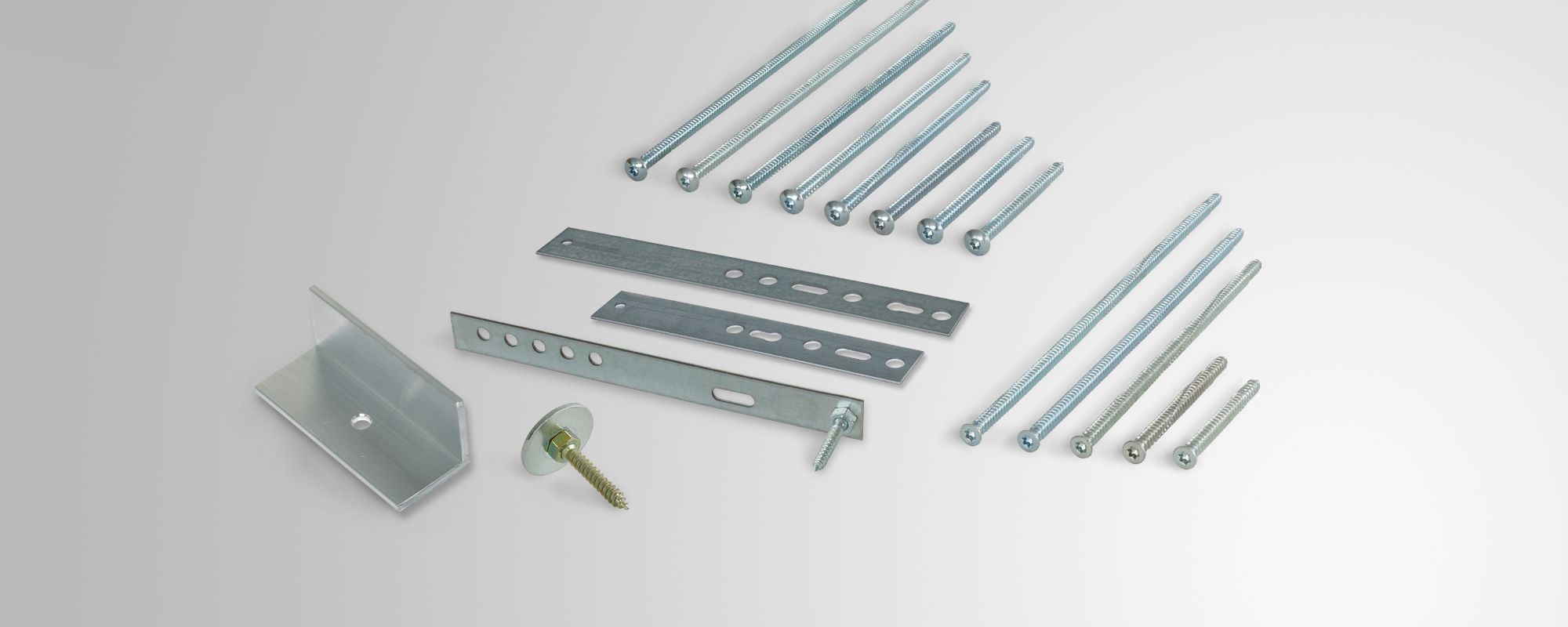

At Fensterbau Frontale 2026, ISO-Chemie will be showing how modern building sealing is conceived and implemented today under the motto “Sealing – Next Level.” Innovative technologies such as “HYFI-TECH” open up new possibilities for a safe and energy-efficient building envelope. At the trade fair stand, the international trade audience will gain exclusive insights into developments and system solutions at ISO-CHEMIE.

Learn more